What is a KDS System? The Ultimate Guide for Modern Restaurants

Restaurant operators often ask what is a kds system when a busy Friday night turns into chaos – lost tickets, printers piling up orders, chefs shouting across the kitchen, and growing confusion about what should be prepared next. A KDS is not just a screen replacing paper tickets; it’s the operating system of the kitchen, designed to bring order, speed, and control when volume peaks and traditional communication breaks down.

In this article, you will learn:

- The comprehensive definition of what is a KDS system and how it replaces traditional kitchen printers.

- How the data flows in real-time from the POS directly to the kitchen screens to eliminate communication errors.

- The key operational benefits: from reducing ticket times to cutting down on food waste.

- The difference between basic order display and advanced features like "coursing" and "station routing".

- Why investing in a KDS system provides valuable data analytics that paper tickets simply cannot offer.

Definition: What is a KDS System exactly?

A KDS (Kitchen Display System) is a digital software and hardware solution that displays orders from the POS to the kitchen staff in real time, replacing paper tickets. In short, what is a kitchen display system? It’s the core tool that connects ordering channels with the kitchen and orchestrates execution inside the Back-of-House (BOH).

How a KDS Works

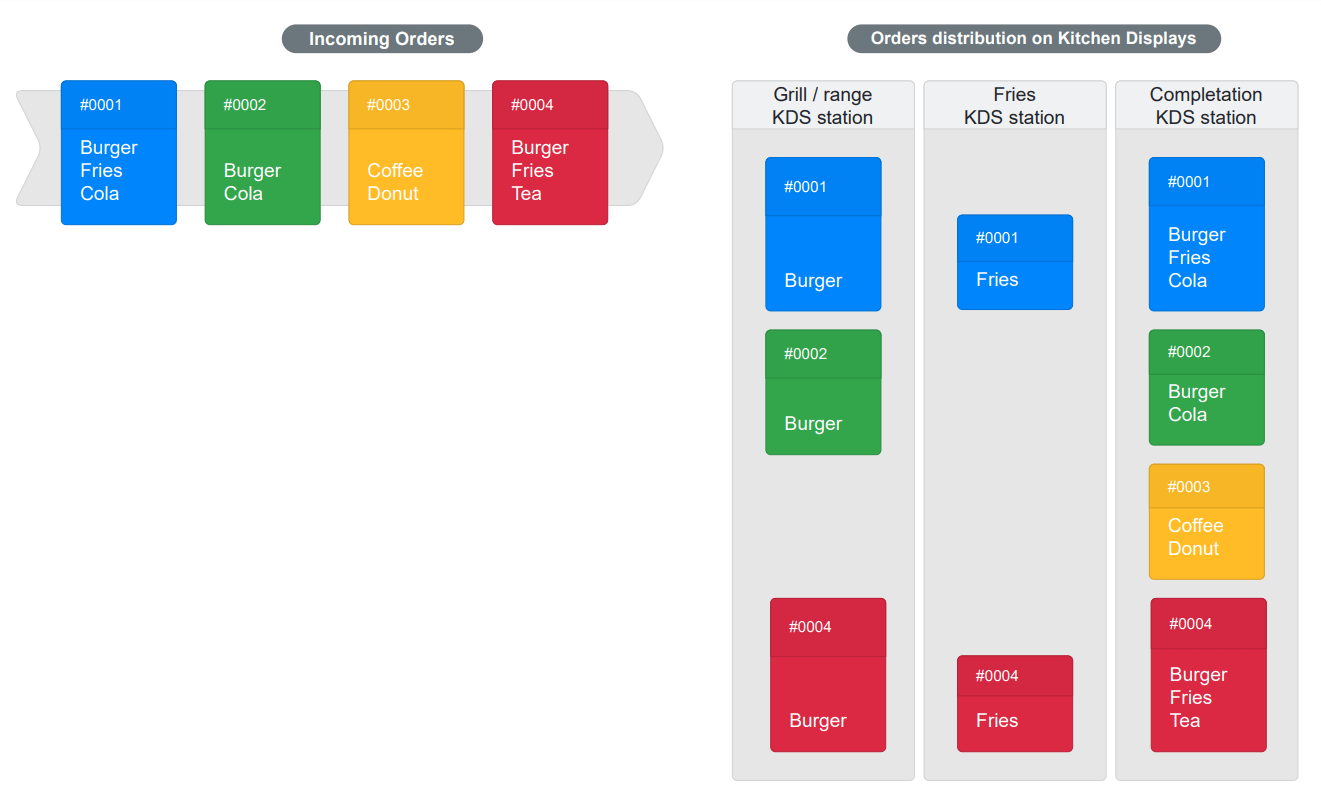

So, how does a kitchen display system work in practice? A KDS connects every ordering point – POS, online ordering, mobile apps, and self-order kiosks – and routes those orders directly to kitchen screens. Orders appear instantly in a clear, prioritized queue, enabling precise order routing, accurate ticket times, and a fully paperless kitchen.

Beyond simple display, modern KDS solutions actively manage the kitchen workflow. They exchange status updates between cooks, cashiers, waiters, and even customer-facing screens, showing progress, delays, or ready states. More advanced systems preprocess orders – coordinating preparation steps (grill, fry, assemble) so items finish together and food quality stays high. At the expo station, teams can verify, stage, and release orders with confidence.

Core Components

A complete KDS consists of:

-

Software – the intelligence layer (e.g., Ordering Stack) that manages queues, timing logic, communication, and analytics.

-

Hardware – touchscreens and/or bump bars mounted in the kitchen to display, acknowledge, and complete orders quickly.

Used correctly, a Kitchen Display System becomes the operational pivot of the restaurant. It reduces waiting time, lowers errors, and improves customer experience – critical when even a couple of minutes can decide satisfaction during peak hours.

How Does a KDS Work? (The Workflow)

A Kitchen Display System streamlines the entire kitchen workflow by replacing manual communication and paper tickets with a real-time, digital process. Here’s how it works step by step inside the Back-of-House (BOH):

Step 1: Order Is Placed

An order is taken through any channel – POS, self-order kiosk, or mobile/online ordering. Regardless of the source, the order enters the system in a standardized digital format, eliminating misunderstandings and creating a truly paperless kitchen.

Step 2: Instant Transmission

The order is instantly transmitted to the KDS server. There’s no printing, no walking tickets to the kitchen, and no verbal handoff. This immediacy is critical for controlling ticket times during peak hours.

Step 3: Intelligent Routing

Using predefined rules, the system performs precise order routing. Drinks are sent to the bar screen, burgers to the grill station, and sides to the fry station. Each kitchen station sees only what it needs to prepare, reducing noise and improving focus.

Step 4: Status Updates and Handoff

When a chef completes an item, they “bump” the order on the screen. The status updates in real time, triggering a “Ready” notification for the front of house or the expo station, where orders are assembled and released. This closed feedback loop keeps teams synchronized and service flowing smoothly.

By digitizing every step – from order intake to final handoff – a KDS turns kitchen operations into a coordinated, fast, and reliable system built for volume and precision.

KDS vs. Kitchen Printers: Why Switch?

For years, kitchen printers have been the standard in restaurant Back-of-House (BOH) operations. But under pressure, their limitations become obvious. Printers are noisy, run out of paper at the worst possible moment, and tickets can easily fall on the floor, get lost, or be prepared out of order. Most importantly, paper tickets provide no visibility into ticket times, performance, or bottlenecks – leaving managers blind during peak hours.

A Kitchen Display System changes this completely.

Why Printers Hold Kitchens Back

-

Paper tickets can be lost, damaged, or ignored

-

No real-time overview of the kitchen workflow

-

No data on preparation times or delays

-

Chaotic communication between stations and the expo station

In high-volume environments, this leads to miscommunication, overworked teams, and frustrated customers.

Why KDS Is the Better Choice

A KDS keeps all orders in one centralized, digital stream – ensuring no orders are ever lost. Orders are queued intelligently and displayed clearly, allowing teams to manage preparation efficiently and in the right sequence. This results in smoother workflows, better coordination, and faster service.

Key advantages include:

-

Silent operation – no printers, no noise

-

Paperless kitchen – eco-friendly and more reliable

-

Order routing – items go directly to the correct stations

-

Preparation time tracking – full visibility into ticket times

-

Color-coded alerts – instant visual warnings for delays or bottlenecks

By digitizing communication and execution, a KDS transforms the kitchen into a controlled, data-driven environment. It doesn’t just replace printers – it upgrades the entire operation, helping teams stay calm, organized, and efficient even during the busiest shifts.

Read also: How to Organize a Kitchen for Efficiency

Key Features to Look For

Not all Kitchen Display Systems are created equal. The real value of a KDS lies in its sophistication and its ability to optimize the kitchen workflow across the entire Back-of-House (BOH). When evaluating a system, these are the key features that separate basic screens from truly operational tools.

1. Intelligent Routing

At its core, a KDS must support precise order routing. Specific items should be sent automatically to the correct stations – burgers to the grill, fries to the fryer, desserts to the cold station. Advanced routing also takes into account equipment availability and workload, ensuring the kitchen operates at peak efficiency without overloading any single station.

2. Coursing and Order Grouping

Effective coursing is critical for timing and quality. A modern KDS groups items by course –

starters, mains, sides – so they are prepared and finished in the right sequence. This coordination ensures dishes arrive together, fresh and on time, and helps maintain predictable ticket times, even during busy service.

3. All-Day View

The all-day view gives the kitchen instant awareness of total demand. Instead of focusing only on individual tickets, the team sees aggregated counts such as “5 burgers on the grill now” or “3 starters pending.” This feature helps chefs plan ahead, manage resources, and reduce last-minute pressure – especially at the expo station, where timing is critical.

4. Workflow and Time Management

Beyond displaying orders, a strong KDS actively manages the kitchen workflow. It can prioritize items with longer prep times, coordinate parallel cooking processes, and reduce idle time across stations. By digitizing instructions and sequencing, the system brings structure and consistency to even the busiest kitchens.

5. Data and Integrability

A KDS is also a powerful source of operational data. Insights into throughput, bottlenecks, and preparation speed help managers refine promised delivery times and optimize staffing. When integrated into a paperless kitchen, modern KDS solutions connect seamlessly with POS systems and other tools, becoming a core component of a scalable restaurant technology stack.

Choosing a KDS with these features ensures the system does more than replace printers – it actively improves performance, consistency, and control in the kitchen.

Summary

The answer to what is a kds system is simple: it is the tool that brings order to chaos. When kitchens are overwhelmed by peak-hour volume, paper tickets, shouting, and guesswork quickly break down. A KDS replaces that disorder with real-time visibility, structured workflows, and clear priorities – turning the kitchen into a coordinated, data-driven operation instead of a reactive one.

See how Ordering Stack’s KDS integrates with your existing POS.